![]()

Production process chains, Micro-deep-drawing

No product is produced in one working step. There always exists process

chains – whether in the product development or in the mass production.

The interaction in such process chains requires a fundamental understanding

of the engaged processes, as well as the boundary conditions and interfaces.

A process chain consists of a starting point, the single processes, the

interactions between processes and the product. Thereby the interactions

have a particular, often underestimated importance.

Horizontal and vertical process chains can be distinguished. A process

chain starting from the raw material to the end product may be understood

as a horizontal process chain. Whereas, the procedure from the conception

to the product may be understood as a vertical process chain. This process

chain contains different processes than the horizontal one. Next to construction

and FEM-modelling, the prototyping, especially the rapid tooling plays

a predominant role.

Obtaining the long term aim, the improvement of the process chains, queries

about the quality management and the optimisation need to be answered.

The properties of the incoming product determine the process efficiency

and consequently the results. Looking at the micro-deep drawing process

for example Figure 1, the dependency of the results,

e.g. the maximum drawing ratio, as well as the incoming product on the

process, is obvious. Depending on the material a reduction or a rise of

the attainable limit deep drawing limit occurs at the transition of the

deep-drawing to the stretch-forming.

Bild 1:

Grenzziehverhältnisse bei unterschiedlichen Stempelgeometrien und

Werkstoffen

DMicro-deep-drawing works in the same way as macro-deep-drawing,

where a punch draws the blank into the draw ring and the blank holder

presses against the flange area of the blank and prevents thereby wrinkling

but still allows the material to flow in this area, Figure 2.

The punch diameter can be down to 0.5 mm and the sheet thickness down

to 20 µm for micro-deep-drawing processes. If the process parameters

of micro-deep-drawing and macro-deep-drawing are compared, then scaling

effects can be determined. This is especially interesting for tribological

effects, because friction is increasing, if geometrical parameters are

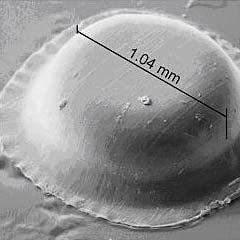

scaled down. Figure 3 shows a deep-drawn micro-cup from

aluminium.

Bild 2:

Prinzipskizze des Tiefziehens

Bild 3:

Deep-drawn micro-cup, punch

diameter 1 mm, sheet thickness 20 µm,

drawing ratio 1.8